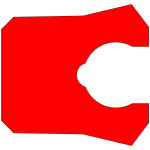

PRS07

Symmetrical, single acting piston/rod seal. Increased preload due to an additional O-Ring. Excellent static and dynamic sealing performance. Excellent performance in low pressure conditions. Used for short pulsating strokes. No reverse leakage when changing direction. Recommended for positioning or holding under pressure.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

400 bar/5800 psi

400 bar/5800 psi

400 bar/5800 psi

150 bar/2200 psi

150 bar/2200 psi

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

NBR 70

NBR 70

NBR 70

NBR 70

NBR 70

PRS10SP

Variable support ring for vee packings PRS10-12 Excellent static and dynamic sealing performance. Excellent performance in high pressure conditions. Useable for short and long stroke lengths. High wear resistance.

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

Contact us

POM P101-WE NBR 70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

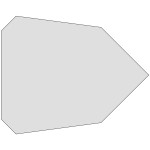

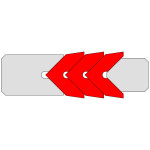

PRS10-12

Symmetrical, single acting piston/rod seal, combined with pressure ring and support ring. By adjusting the number of packings friction and leakage characteristics can be influenced. Excellent static and dynamic sealing performance. Excellent performance in high pressure conditions. Useable for short and long stroke lengths. High wear resistance.

-30°C to +105°C

-200°C to +260°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

500 bar/7200 psi

500 bar/7200 psi

300 bar/4300 psi

300 bar/4300 psi

300 bar/4300 psi

PU Red U203-95

PTFE-25% Carbon T125-C25

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

POM P101-WE NBR 70

PEEK PK100-CN FPM 75

POM P101-WE NBR 70

PEEK PK100-CN

PEEK PK100-CN

PRS13-15

Symmetrical, single acting piston/rod seal, combined with pressure ring and support ring. By adjusting the number of packings friction and leakage characteristics can be influenced. Excellent static and dynamic sealing performance. Excellent performance in high pressure conditions. Useable for short and long stroke lengths. Reduced friction compared to PRS10-12 profile especially in the high pressure range.

-30°C to +105°C

-200°C to +260°C

-25°C to +100°C

-25°C to +150°C

-20°C to + 210°C

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

500 bar/7200 psi

500 bar/7200 psi

300 bar/4300 psi

300 bar/4300 psi

300 bar/4300 psi

PU Red U203-95

PTFE-25% Carbon T125-C25

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

POM P101-WE NBR 70

PEEK PK100-CN

POM P101-WE NBR 70

PEEK PK100-CN

PEEK PK100-CN

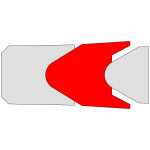

PRS18

Symmetrical, single acting piston/rod seal, no interference on the ID or OD. Increased preload due to an additional O-Ring. Sharp lips for use in high viscosity media. Excellent static and dynamic sealing performance. Good performance in all pressure ranges. Used for short pulsating strokes. No reverse leakage when changing direction. Recommended for positioning or holding under pressure.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

400 bar/5800 psi

400 bar/5800 psi

150 bar/2200 psi

150 bar/2200 psi

150 bar/2200 psi

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

NBR70

NBR70

NBR70

FPM75

FPM75

PRS19B

Symmetrical, single acting piston/rod seal, no interference on the ID or OD. Preload effected through round Helicoil-spring which ensures high pressure on the sealing edges. Excellent static and dynamic sealing performance. Excellent sealing performance in low and high pressure ranges. Useable for short and long stroke lengths. Low friction in dry running or poor lubrication conditions. Also used for gas applications. Negligible tendency to “stick-slip” effect, small break away loads.

-200°C to +80°C

-200°C to +260°C

-200°C to +260°C

-200°C to +260°C

5 m/s

5 m/s

5 m/s

5 m/s

* (0.1 m/s

rotating)

* 150 bar/2200 psi

* 150 bar/2200 psi

* 150 bar/2200 psi

* 150 bar/2200 psi

UHMWPE

PTFE T101-W

PTFE-40% Bronze T120-BR40

PTFE-25% Carbon T125-C25

PRS19C

Symmetrical, single acting piston/rod seal, no interference on the ID or OD. Preload effected through Helicoil-spring which ensures high pressure on the rounded sealing lips.. Excellent static and dynamic sealing performance. Excellent sealing performance in low and high pressure ranges. Useable for short and long stroke lengths. Low friction in dry running or poor lubrication conditions. Also used for gas applications. Negligible tendency to “stick-slip” effect, small break away loads.

-200°C to +80°C

-200°C to +260°C

-200°C to +260°C

-200°C to +260°C

5 m/s

5 m/s

5 m/s

5 m/s

* (0.1 m/s

rotating)

* 150 bar/2200 psi

* 150 bar/2200 psi

* 150 bar/2200 psi

* 150 bar/2200 psi

UHMWPE

PTFE T101-W

PTFE-40% Bronze T120-BR40

PTFE-25% Carbon T125-C25

PRS19D

Symmetrical, single acting piston/rod seal, no interference on the ID or OD. Preload effected through round Helicoil-spring which ensures high pressure on the sealing edges. Excellent static and dynamic sealing performance. Excellent sealing performance in low and high pressure ranges. Useable for short and long stroke lengths. Low friction in dry running or poor lubrication conditions. Negligible tendency to “stick-slip” effect, small break away loads.

-200°C to +80°C

-200°C to +260°C

-200°C to +260°C

-200°C to +260°C

2 m/s

2 m/s

2 m/s

2 m/s

200 bar/2900 psi

200 bar/2900 psi

200 bar/2900 psi

200 bar/2900 psi

UHMWPE

PTFE T101-W

PTFE-40% Bronze T120-BR40

PTFE-25% Carbon T125-C25

PRS22

Symmetrical, single acting piston/rod seal, no interference on the ID or OD. Stabilisation of the sealing ring by an additional retainer ring. Excellent static and dynamic sealing performance. Excellent performance in low pressure conditions. Useable for long stroke lengths. Negligible tendency to “stick-slip” effect above a speed of 0.15 m/s.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

400 bar/5800 psi

400 bar/5800 psi

150 bar/2200 psi

150 bar/2200 psi

150 bar/2200 psi

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

POM P101-WE NBR 70

PEEK PK100-CN FPM 75

POM P101-WE NBR 70

PEEK PK100-CN

PEEK PK100-CN

PRS99

Variable pressure ring for vee packings PRS10-12 Excellent static and dynamic sealing performance. Excellent performance in high NBR 70pressure conditions. Useable for short and long stroke lengths. High wear resistance.

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

400 bar/5800 psi

150 bar/2200 psi

150 bar/2200 psi

150 bar/2200 psi

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

NBR 70

FPM 85

FPM 85

BUR08

Normally cut at an angle for easy installation, but also available as non-split version. Low dynamic friction. Low break-away forces after long standstills. Activated back-up rings reduce extrusion gap and prevent twisting of the seal in the groove.

-30°C to +105°C

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BUR09

Especially designed for use with O-Rings. Improved form stability of the elastomer O-Ring. Bigger contact area of the O-Ring compared to BUR08 creating less deformation. Normally cut at an angle for easy installation, but also available as non-split version. Low dynamic friction. Low break-away forces after long standstills. Activated back-up rings reduce extrusion gap and prevent twisting of the seal in the groove.

-30°C to +105°C

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BUR10

Back-up rings or Anti Extrusion Rings do not have a sealing function. They are designed to prevent elastic sealing elements of extrusion gap. Features Active Anti Extrusion Ring for Piston Seal PS02. Reduced gap extrusion of the elastomer seal and/or higher pressures up to 700bar possible Prevention of twisting of the seal in the groove. Available as split non-split version.

-30°C to +105°C

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BUR11

Active Anti Extrusion Ring for Rod Seal RS02. Reduced extrusion gap of the elastomer seal and/or higher pressures up to 700bar possible Prevention of twisting of the seal in the groove. Available as split non-split version.

-30°C to +105°C

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BUR12

Triangular Anti Extrusion Ring for Rod applications. Special housing designs required. Reduced extrusion gap of the elastomer seal and/or higher pressures up to 700bar possible. Available as split and non-split version.

-30°C to +105°C

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BUR13

Triangular Anti Extrusion Ring for Piston applications. Special housing designs required. Reduced extrusion gap of the elastomer seal and/or higher pressures up to 700bar possible. Available as split and non-split version.

-30°C to +105°C

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BWR01

Normally cut at an angle for easy installation, but also available as non-split version. Low dynamic friction. Low break-away forces after long standstills.

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

Contact us

Contact us

Contact us

Contact us

N/A

N/A

N/A

N/A

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BWR01A

Spiral groove on the outside diameter for better lubrication Normally cut at an angle for easy installation, but also available as non-split version. Low dynamic friction. Low break-away forces after long standstills.

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

Contact us

Contact us

Contact us

Contact us

N/A

N/A

N/A

N/A

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BWR03

Normally cut at an angle for easy installation, but also available as non-split version. For use in piston applications. Design combines guiding and back-up ring function. Low dynamic friction. Low break-away forces after long standstills.

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

Contact us

Contact us

Contact us

Contact us

N/A

N/A

N/A

N/A

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75

BWR04

Normally cut at an angle for easy installation, but also available as non-split version. For use in rod applications. Design combines guiding and back-up ring function. Low dynamic friction. Low break-away forces after long standstills.

-60°C to +100°C

-200°C to +80°C

-200°C to +260°C

-50°C to +250°C

Contact us

Contact us

Contact us

Contact us

N/A

N/A

N/A

N/A

POM P101-WE NBR70

UHMWPE

PTFE-25% Carbon T125-C25

PEEK PK100-CN FPM75